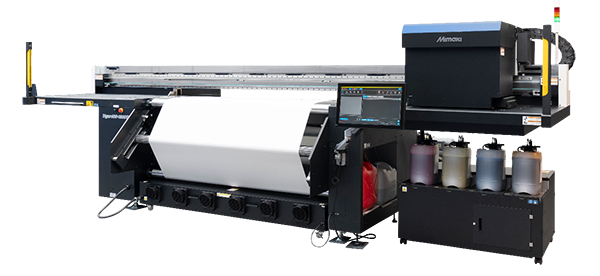

Tiger600-1800TS

Mimaki dye-sublimation transafer printer lineup

Textile inkjet printer with belt conveying system

MIMAKI Tiger600-1800TS

Currently, the majority of the world’s textile products are concentrated in a few producing countries and are produced using analog printing. Analog textile printing is a complicated and lengthy production process that requires long lead times for shipment to consumer countries. Therefore, apparel brands and retailers in the consuming countries are required to keep inventories to prevent lost sales opportunities due to shortages, and there is a risk of unsold products, cost incurred by disposal, and environmental impact. In addition, analog textile printing involves frequent exposure to chemical for ink formulation and printing plate cleaning, which posed a safety issue for printing operators.

Feature

1. It is equipped with Mimaki Printer Controller New!

Touch-screen based printer operation software is installed on our system. Because this printer has been designed for one touch ease of operation, you can set up, operate it and output data from it with one-touch simple operation.

One touch job selection

You can also check at a glance remaining amount of ink.

Suspending and restarting of operation during printing are also easier with a single touch.

2. “Nozzle Recovery System” for continuous operation New!

When any clogging of a certain nozzle cannot be solved even after cleaning is performed for it, such nozzle will not be used, and another normal nozzle will be used instead (nozzle recovery function).

In this way, it becomes possible to perform the ongoing print job continuously.

Creation of nozzle recovery data is also available now from the touch panel.

3. Mimaki Advanced Pass System 4 (MAPS4) is supported New!

Smooth prints can be realized by printing pass boundaries fading in gradation, while banding (horizontal stripes), uneven color, or glossy streak can be reduced.

4. Ethernet 10GB-T supported New!

Added support for 10GB-based Ethernet controller. Print data transfer at higher speed is now available.

5. Selectable print mode to suit the production (from high-speed to high-quality)

For the realization of higher quality of print, 1,200 dpi print mode is added and the multi-pass is applied.

Tiger-1800B MkIII will apply the production from the high-speed print regarding much importance for productivity to the high-quality print of beautiful image.

Specifications

| Item | Tiger600-1800TS |

|---|---|

| Print speed | Max: 550 m2/h |

| Number of heads | 8 heads (2 staggers × 4 in-lined) |

| Ink set | Sublimation dye ink MLSb510 / 4 colors (BL/M/Y/K) |

| Ink capacity | 10 kg ink tank |

| Maximum printout width | 1,850 mm (72.8″) |

| Maximum media settable width | 1,900 mm (74.8″) |

| Maximum media thickness | 5.0 mm or less (Head gap: 1.5 mm to 3.0 mm) |

| Mountable roll type | Smaller one from among 300 kg (661 lb) or less type and Φ600 mm (23.6″) or less type |

| Main operation unit | MPC for Tiger600 (LCD touch-screen monitor) |

| External connection interface | Ethernet 10GB-T, USB3.1 / USB2.0 (via removal disk) |

| Power specifications | AC 3-phase 4-line 380-415±5% 50/60Hz±1%, 30A or less |

| Operating environment | Operating temperature range: 20 to 30 °C, Operating humidity range: 35 to 64% RH (no condensation) |

| External machine dimensions | 5,350 mm x 3,300 mm x 1,920 mm (211″ x 130″ x 76″) |

| Machine weight | 1,620 kg (3,571 lb) |

| Drying heater | A fan heater is mounted at the bottom of the main unit. |

| RIP Software | TxLink4 Standard / TxLink4 Professional |

*Specifications, designs, dimensions, and other information described in this document are subject to change without notice due to technical improvement etc.

Maximum output speed

Downloads

Select ink.

TxLink3 / TxLink4

| Model | Color set | Ink | |

|---|---|---|---|

| Tiger-1800B MkIII | 4 colors | BMYK | MLSb510 MLSb520 |

| 8 colors | CMYKLkOrRB | MLRc500 | |

When PDF file cannot be opened in Internet Explorer, please download the file to your computer as described below. [Right-click -> Select “Save Target As…”]

| Name | Version | File size |

|---|---|---|

| ML Tiger-1800B MKIII Operation Manual | 1.1 | 22.31MB |

| ML Tiger-1800B MKIII How to clean and maintenance | 1.3 | 5.89MB |